The beverage industry has observed exceptional evolution throughout the years, largely driven by developments in producing modern technology. One of the foundation tools fueling this progression is the bottle blowing machine, an essential tool for creating plastic containers efficiently and cost-effectively. Among the various kinds of these makers, the automatic blow molding machine attracts attention as a result of its speed, precision, and capacity to handle high quantities, making it a preferred choice for manufacturers worldwide.

These machines operate on a basic concept of transforming plastic preforms right into completely created containers. The process begins with the injection molding of preforms, which are then warmed and broadened in a mold to take the wanted shape. PET Blow Molding Machines, typically used in the production of containers for beverages, rely upon Polyethylene Terephthalate (PET) as the primary product for making light-weight, solid, and recyclable bottles. Provided the expanding demand for ecologically pleasant items, PET bottles have surged in popularity, motivating manufacturers to look for effective production approaches.

For companies looking to profit from the thriving water and soft drink market, purchasing a PET bottle making machine is vital. These machines not just guarantee premium production but also optimize sources and minimize waste. They come outfitted with advanced functions like programmable logic controllers (PLCs) that provide real-time surveillance of manufacturing processes. This makes certain constant quality throughout sets and enhances the machine's integrity.

The 2 cavity pet blowing machine is an exceptional option for little to medium ventures looking to create moderate volumes of containers without extreme equipment prices. As manufacturings scale up, firms frequently move to larger jobs requiring a 4 cavity pet blowing machine.

For high-demand production settings, the fostering of a 6 cavity pet blowing machine can produce additional advantages. With this machine, manufacturers can dramatically increase their manufacturing prices, enabling them to meet immediate market demands while keeping high-quality criteria. Such effectiveness not only improves profit margins but likewise positions firms as reputable providers in the hectic drink market.

As manufacturers take into consideration the ideal equipment for their demands, it ends up being increasingly crucial to understand the landscape of pet bottle making machine manufacturers. Leading vendors usually supply a combination of top quality, service, and technological technology that can considerably affect the production procedure. Collaborating with skilled manufacturers makes certain that companies get not only high-performing makers but likewise crucial assistance in terms of maintenance and training.

In addition, the sustainability aspect of assembly line can not be forgotten. As problems over plastic waste expand, numerous manufacturers are currently looking for ways to integrate recycled products into their production processes. This is specifically relevant when talking about bottle blowing makers that make use of PET, as R-PET (recycled PET) is an increasingly practical alternative for generating new bottles. Furthermore, the execution of environmentally friendly methods in the production procedure not only follows policies yet additionally enhances a brand's photo in the eyes of consumers that increasingly require lasting techniques.

In light of these advancements, the market for bottle blowing machinery is becoming significantly competitive. Technologies such as energy-efficient equipment, enhanced automation, and incorporated high quality control systems are changing exactly how bottle manufacturing is come close to.

Buying sophisticated innovation, such as AI-driven automation, can further boost the top quality and performance of production lines. These systems frequently include read more anticipating maintenance, which utilizes data analytics to anticipate machine failures prior to they occur, thus considerably reducing downtime and improving efficiency.

Additionally, business are additionally accepting new styles and functionalities for their bottles. Modification in bottle sizes and shapes needs functional blow molding makers with the ability of fast modifications without calling for substantial downtime-- a feature that contemporary automatic blow molding machines supply effectively. This versatility permits manufacturers to respond swiftly to altering customer preferences, from smooth, modern-day water bottles to extra traditional forms that stimulate a sense of nostalgia.

Sector collaboration likewise welcomes technology; sharing insights between vendors, end-users, and manufacturers can lead to substantial renovations in materials utilized and processes complied with. Such partnerships can improve quality assurance and assist in a much better understanding of market demands, leading to much more targeted machine styles and functions.

In addition to the devices made use of, training and ability development for drivers is an additional important consider optimizing making use of pet bottle making equipments. Trained labor force implies that firms can exploit on the full abilities of their equipment, bring about boosted effectiveness, minimized waste, and higher-quality final result. Guaranteeing constant learning and adjustment enabled by a vibrant industry landscape ensures manufacturers remain affordable.

The success of the beverage industry, especially in the PET bottle sector, rests on the development and effectiveness of manufacturing lines. The development of the bottle blowing machine, particularly automatic ones, stands for a vital shift towards attaining greater productivity and sustainability. As companies function to line up with customer expectations while managing operational efficiencies, machinery manufacturers play a crucial role fit the future of product packaging remedies.

The tools landscape-- from 2 cavity to 6 cavity pet blowing devices-- has actually catered to a range of abilities and needs, motivating services to optimize their production effectiveness. In doing so, business not just satisfy current consumer needs but potentially set new standards in sustainability and high quality assurance. All signs point towards the proceeded importance of PET bottle manufacturing innovation as organizations aim to introduce, grow, and adapt in an affordable marketplace where the stakes have actually never been greater.

Looking ahead, it ends up being critical that brand-new players keen on getting in the market meticulously consider their machinery financial investments-- examining not simply the immediate capabilities however the durability and flexibility in the face of fast sector changes. The capability to create eco-friendly and varied offerings will be essential in this evolving landscape that continues to stress sustainability as a core tenet of consumerism. Ultimately, accepting advanced innovation, focusing on collaboration, and focusing on performance will certainly be the essential chauffeurs pushing the bottle blowing and beverage sectors right into a promising future.

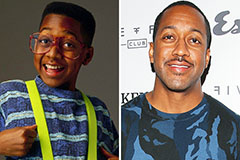

Jaleel White Then & Now!

Jaleel White Then & Now! Jonathan Taylor Thomas Then & Now!

Jonathan Taylor Thomas Then & Now! Hailie Jade Scott Mathers Then & Now!

Hailie Jade Scott Mathers Then & Now! Kelly Le Brock Then & Now!

Kelly Le Brock Then & Now! Nicholle Tom Then & Now!

Nicholle Tom Then & Now!